High

temperature and high material layer (PSH) technology pilot study in our laboratory

get success

High temperature and high temperature and high material layer material layer

(PSH) technology pilot study in our laboratory get success, before and after

the 2013 Spring Festival period more than a month Northeastern University Dr. Jiang Xin and our

R & D personnel in my company R & D center laboratories (PSH) direct

reduction process pilot get a huge success

High

temperature direct reduction process material layer (PSH) is put forward

by Canada McMaster University Chinese

metallurgists professor Lu weigao(WK LU) at the late 1990s, at the beginning of

the 21st century, the US Department of Energy funded McMaster University to

test the development and some laboratory studies, the disciple of Lu weigao (WK

LU) of Northeastern University professor

Dr. Jiang Xin in 2011 signed a joint development agreement with our company,

the high temperature and high material layer technology (PSH) and the

reciprocating car bottom furnace process (OTS) combined to become OP process,

after-market applications, as our company's fourth-generation product, with the

"four high" features of high energy efficiency, high productivity,

high metal ratio, high strength and density ,which can be used either to

replace coal generation of blast furnace ironmaking coke production, and also

suitable for processing iron ore and special waste, and it can greatly improve

the existing single reciprocating car hearth furnace capacity, it has good

prospects, at the same time, it get great concern at home and abroad.

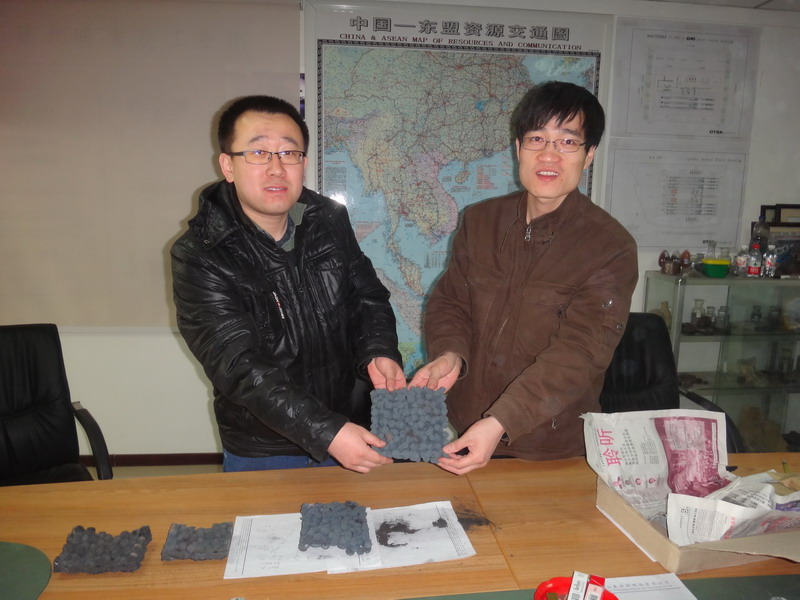

The test

material thickness is 11.5cm, reducing time is 50min, context layer have good reduction

effect, achieved the desired purpose. Below is Dr. Jiang Xin (left) and our

company deputy general manager Wang Xiangyu (right) are checking the high

temperature and high material layer test products.