Car bottom furnace direct reduction process make copper slag into DRI with copper

Wang Jianchun Liu Rongxing Wang Xiangyu Wang chuanjie

(Tangshan outstanding science and technology Co., Ltd., Tangshan 063020)

Abstract: This paper introduces the car bottom furnace direct reduction processing metallurgical slag, and taking copper slag as the example.

Keywords: processing metallurgical slag; non-blast furnace iron smelting; car bottom furnace technology; DRI

Introduction

In recent years, although the scale of our country’s resource development is increasingly expanded, the utilization rate is still low, which has not reached generally less than 40% in total, there is great room for upgrading improvement. It is estimated that China's annual recycled without recycling renewable resources can be reached up to worthy $ 35 billion to $ 40 billion, each year about 5 million tons of scrap steel and about 20 million tons of scrap non-ferrous and precious metals, a large waste plastics, waste glass are not recycled and reused. With the rapid development of China's iron and steel industry, domestic iron ore cannot meet the demand of steel production, resulting that the majority of large-scale iron and steel enterprises have to pay high prices for iron ore from Australia, Brazil, India and other countries. Since 2003, China's iron ore supply and demand gap was further expanded, even in the economic downturn of 2008, imports iron ore has reached 444 million tons, and import dependency is 49.5%. In addition, a serious shortage of scrap in China resulting in a lot of electric steel plant in a semi-shutdown state, according to statistics, the shortfall gap of scrap was more than 2,000 tons in 2012. Therefore, the search for new steel raw materials becomes one of the imminent tasks of China's steel industry. In recent years, for some iron metallurgical slag, China's relevant scientific researchers has breakthrough the process concepts of the traditional dressing - sintering - blast furnace, they put forward the methods of sorting election after the first smelting, using the first rule method known as "deep reduction - efficient sorting" process to deal with these metallurgical slag, to achieve the effective utilization of iron enrichment and resources. After getting high metal ratio cold briquetting, this is not only supple scrap, but also the high-quality raw materials for smelting steel, special steel.

It is in this background, it takes us more than four years of hard study and experimental research; put the introduction of the car bottom furnace reduction process system metallurgical processing and comprehensive utilization of waste residue. The most important characteristic feature of this process is the ability to maximize the recovery of iron and metallurgical slag valuable elements, and to ensure a high rate of metal.

In this article, we selected a representative copper slag "deeply reduction and efficient separation" semi-industrial tests as the example discuss the process.

1 Method

1.1 the raw material preparation

The test adopted copper slag for raw materials, its main chemical components are shown in table 1.1, we selected the anthracite coal as reducer, its main components are shown in table 1.2. In addition, and our experiments also used additives.

1.2 Test Equipment

Reduction equipment designed by Tangshan outstanding science and technology Co., Ltd, and manufactured the OTS-8 car bottom furnace; its temperature measurement accuracy is ± 5 ℃. In addition the test is also used XCGS-73 type ф5 0 magnetic tube and XMQ-ф240 × 90 cone ball mill and other equipment.

1.3 Test procedure

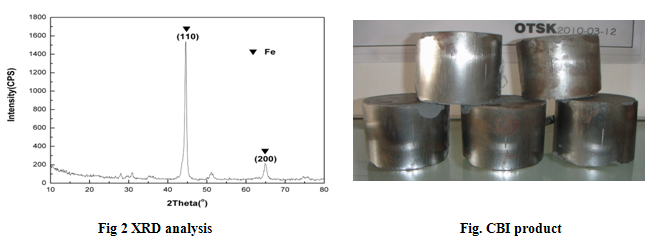

Adoption charge mold, minerals, reducer as well as amount of additives mixed and then be put on surface of the furnace car, through the procedure of preheated, high temperature reduction, cooling. After exit the furnace material released directly by water quenching process, grinding magnetic materials are obtained after water quenching product - reduced iron powder. By the laboratory testing for the product Fe, Cu content, we also make analysis on the product of XRD phase and SEM morphology and EDS spectrum analysis in order to study reduction mechanism.

2. Test results

2.12 Copper Slag

Through repeated research and experiments, using the car bottom furnace reduction, reducing temperature at 1200 ℃ ~ 1300 ℃, reducing time was 100 ~ 120min, experiments show that adopt 1 # additive, combined with weak magnetic and magnetic composite magnetic technology was the best, its weak magnetic concentrate iron content was up to 95.44%, the recovery rate was 91.50%, metallization rate was 96.19%.

3 reduction mechanism analysis

The main component of Copper Slag is copper silicate and magnetic iron oxide, amorphous vitreous fayalite (Iron olivine) (2FeO • SiO2), magnetite (Fe3O4) and some gangue composition. Copper smelting slag mainly exists in matte or in states of simply chalcocite (Cu2S), which is almost free of metallic copper, copper sulfide was more common in small droplets distributed in the form of a discontinuous phase of iron olivine and glass.

According to copper, iron oxide reduction of Gibbs free energy, we know that copper, iron are easily reduced; while SiO2, MgO and other gangue oxides reduction temperatures are above 1300 ℃. Therefore, we could make use of the reduction features of copper and iron oxide to control the reduction temperature, gangue oxides reduction has not yet started, and copper, iron has been completely reduced. After the deep reduction by magnetic separation, we will be able to separate iron and other impurities and gangue components. The whole difficulty of process lies in the reduction process of reduction of iron olivine, because iron is a strong endothermic process of olivine reduction, and the reaction starting temperature is high, the reaction speed is slow. For the copper dregs, it is a crucial element for the restoring reduction process. Therefore, to increase reducing speed, lower reduction temperature, we usually need to add certain additives to promote the reduction of iron olivine.

The below chemical reaction may be occur:

C+CO2=2CO

△G=166550-171T, J·mol-1 (1)

CuO+C=Cu+CO↑

△G=-238314-198.545T, J·mol-1 (2)

CuO+CO=Cu+CO2

△G=-127794+26.968T,J·mol-1 (3)

3Fe2O3+CO=2Fe3O4+CO2

△G=-52195.1-41.05T, J·mol-1 (4)

Fe3O4+CO=3FeO+CO2

△G=35120-41.55T, J·mol-1 (5)

FeO+CO= Fe+CO2

△G=-17500+21T, J·mol-1 (6)

2FeO·SiO2+2C=2Fe+SiO2+2CO (7)

△G=332041-321.53T, J·mol-1

4 copper reduced iron industrial applications

Copper smelting reduction of iron can be used as the raw material of high weathering structural steels. Weathering steel that is the atmospheric corrosion resistant steel, which is add a small amount of alloying elements in the steel such as Cu, P, Cr, Ni, etc., in order to form surface protective layer for the metal substrate, to improve the weather resistance of steel. Using weather resistance steels is better than using weathering steel of welded structure; it is called high durability structural steel. High weathering structural steel has its the national standard "GB / T 4171-2000", which is specified in the standard that the structural steel can be used as high weathering resistance to atmospheric corrosion (such as Ship board, offshore oil derrick platform, etc.)That is hot-rolled, cold-rolled steel sheet, strip and steel, vehicles, containers, buildings, towers frames and other structures; they are typically used in the delivery condition, which can be made of structural parts for bolting, riveting and welding.

It is known that high weathering structural steel is oxygen converter or electric furnace smelting, the major domestic steel mills are all producing high weathering structural steel, particularly the s steel enterprises which are specializing in the production of special steel, their steel production process is short process, they use scrap steel as raw material for producing ,the special quality steel smelting in an electric arc furnace, because of the factors of raw materials and impurities scrap, steel mills mostly adopted to add a certain proportion of direct reduced iron to replace scrap. From high weathering structural steel grades and chemical composition we know that the chemical composition of various grades of high weathering structural steels Cu content are between 0.25 to 0.55%, At present the smelting mills meet the standards specified content of Cu in high weathering structural steel, they all have taken the way of plus copper, and then iron and copper content of Cu reduction about 0.8%, reduced iron steelmaking being added ratio is generally about 30%, so the reduced iron copper contend Cu is 0.8% ,which will be diluted to the desired content. Adjusting to add the ratio of copper smelting reduction, it can meet the technical requirements for high weathering structural steel grades corresponding Cu contents.

5. Conclusion

(1) The car bottom furnace application reduction combined with magnetic separation of the technology, which enables the reduction of copper waste slag processing to realize iron recycling, the recovery rate is up to 91.50%, metallization rate is up to 96.19 %.

(2) due to its own characteristics, in addition it is not only to achieve the reduction of copper waste slag processing, but also has the capable to other complex and difficult beneficiation of low grade and metallurgical slag, and it improves the deep reduction process of other iron oxides efficient separation, and it can ensure product of higher metal ratio and higher metal recoveries.

(3) The cold briquetting technology products of car bottom furnace reduction are shown in Figure 3, the product has reached the H92 and H94 product standards prescribed by the state administration, in which can be used as raw materials ingredients copper smelting "high weathering steel" .

(4) Reduction of copper slag tailings after separation can be used as building materials (such as micro-glass ceramics, foam ceramics, slag cement and concrete blocks, etc.).

6 Implementation of the industrialization

At present, the Tangshan outstanding science and technology co., LTD is jointly with Northeast university in the national science and technology support project "metallurgical slag lead and zinc iron nickel and other metal recycling technology research and demonstration - nickel copper smelting slag depth reduction - high efficient separation technology research", in the two fields take a low grade difficult to deal with mining and metallurgical slag reduction efficient separation, so as to carry out comprehensive research and market applications, industrialization demonstration line is under construction.

(This article was published in the "2014 second copper slag utilization technologies Symposium Proceedings")