Car bottom furnace high temperature and high material layer direct reduced process research and development

Wang xiangyu Jiangxin Li yongqiang Wang jianchun Wang shouping Shen Fengman

1. Tangshan outstanding science and technology Co.,Ltd Tangshan Hebei 063020

2. Northeast University material metallurgy institute, Shenyang, Liaoning 110004

Abstract: The high temperature and high material layer direct reduction process which use carbon-containing pellet is a highly efficient new technology. This paper describes the development of the study of the process and equipment. The operating characteristics for this process are "high temperature" and "high material layer." Production characterized by "four high", that is, high metallization ratio, high production efficiency, high energy efficiency, high DRI strength and density. The high temperature and high material layer direct reduction equipment is reciprocating car bottom furnace. The process can be used for the production of iron, also suitable for processing iron ore and special waste, and it has a good prospect.

Key words: high temperature; high material layer; direct reduction; car bottom furnace; iron-making

1 Introduction

In recent years, with the rapid development of the blast furnace, the problems are becoming increasingly severe, mainly reflected in: 1) the high cost of iron; 2) coking coal resources become increasingly scarce, the price has gradually increased; 3) coking, sintering, pelletizing and blast furnace production process of "three wastes" pollution. Therefore, to achieve sustainable development, the development of non-blast furnace iron-making is very necessary. Non-blast furnace iron-making including smelting reduction and direct reduction, the carbon consumption analysis for the two production routes can be seen in reference [1].

In the development of the world scope of the direct reduction process, the metallurgical workers take a large number of new technology research and development work at home and abroad, the current production mainly have spirit base shaft furnace direct reduction process, coal based rotary hearth furnace, rotary kiln, tunnel kiln, etc. Among them, each process has its own pros and cons, different production enterprise is mainly based on local ore species, energy, and environmental protection policy objective factors, take different process to meet production needs.

Car bottom furnace high temperature and high material layer direct reduction process is a new direct reduction processes. The process is first raised by the Canadian professor of Chinese metallurgists Lu Weigao at the late 20th century. Its main purpose is dealing with large-scale and efficient production of low-carbon molten iron in shortage of coke resource conditions, or deal with some special ore and iron dust.

Wang Shouping, Gao Bowen and Wang Xiangyu in Tangshan Outstanding Science and Technology Co., LTD design OTS process and put into the reduction equipment - "reciprocating car bottom furnace", it can be adapted in high temperature and high material layer process. The combination of core technology and equipment between them will greatly accelerate the industrialization process of high temperature and high material layer car bottom furnace processes.

2 Process introductions

High temperature and high material layers direct reduction, reduction and oxidation chamber is divided into two chambers (Figure 1) [2]. Reduction process consists of the following four components:

(1) Reduction chamber: carbon reduction iron ore produce metallic iron and CO gas, consumption calories;

(2) CO gas is transferred from the reduction chamber to the oxidation chamber;

(3) The oxidation chamber: CO complete combustion (oxidation) generates CO2, releasing heat;

(4) Heat transfer from the oxidation chamber to reduction room.

Operating characteristics of the process known as "high temperature" and "high material layer." In energy using, the first use carbon chemical energy, the carbon be used as reducer to reducer the iron ore and generate CO; then use the carbon heat energy, CO complete combustion to CO2 to produce high temperature, to provide heat source for the reduction and heating for the ore, and the existence of high material layer prevents the DRI was re-oxidized by CO2. Thus effectively improving the fuel efficiency and reduce fuel consumption.

Figure 2 shows a schematic diagram of high temperature and high material layer process [3]. Two key issues in the process are: 1) heat transfer, the heat is transferred from the upper pellet to the lower pellet, from the surface to the interior of pellets; 2) DRI re-oxidation, to prevent DRI re-oxidation by CO2 and O2. It is because adopted the "high temperature" and "high material layer" operation at the same time, and it can achieve "both high fuel utilization rate and metallization."

3 Theoretical foundations

3.1 High Temperature Operation - accelerate heat transfer, increasing the reaction rate

The so-called high-temperature is CO complete combustion in the oxidation chamber, generating CO2. High-temperature operation has the following four advantages:

(1) Improving fuel efficiency and reduce fuel consumption.

(2) In favor of radiation heat transfer. raising the temperature can greatly improve the thermal radiation heat transfer.

(3) To accelerate the pellets shrink. Previous studies have shown that, the heat transfer is the whole process (including mass transport and heat transmission) restriction step. For initial reduction, it is easy to accept thermal radiation heat transfer for the upper pellet, but the lower pellet is difficult to obtain direct radiant heat transfer. High temperature conditions conducive to the first layer of pellets after reducing the volume shrinkage, material layer porosity is increased, in favor of the radiant heat transfer of the second layer of pellets. ...... And so on, so high temperatures accelerate the pellets shrink, thus contributing to lower radiation heating pellets. The good reduction and contraction of the upper layer of the pellets make DRI has excellent thermal conductivity.

(4) High temperature help speed up the reduction reaction rate, improve production efficiency, especially for special ore processing.

3.2 high material layer operations - prevent DRI re-oxidation; improve the metallization rate and production efficiency

Traditional pellet furnace wall for direct reduction process, the main mean heat transfer is radiation heat transfer, based pellet layer more than two layers, and radiation heat transfer is difficult to transfer heat to the second layer below pellets, so in the actual process of the material layer only 1 or two layers (Fig. 3).

Low layers operation (1 ~ 2 layers of carbon-containing pellets, material layer height is about 20~25 mm), fuel efficiency and DRI re-oxidation have conflict, if (1) improve fuel efficiency, reduce the CO/CO2 values, the DRI is re-oxidation easily, which leading to metallization rate lowly; (2) to prevent oxidation, we must improve the CO/CO2 value, lower fuel efficiency, flame temperature drops, it is hard to guarantee the heat transfer, inadequate internal reduction, resulting in low metallization. Usually, low material layer CO/CO2 value is about 2.0, at the flame temperature is about 1200℃~1350℃, the fuel utilization rate is about 52%, but there are still some DRI is oxidized, resulting in a lower metallization ratio, usually less than 70%.

The so-called high material layer, which is 5 to 7 layers in pellets, with a total height of about 80 ~ 120mm. High material layer operation has the following advantages:

(1) To prevent DRI re-oxidation. CO airflow produced by the under layer pellets has a protective effect for the upper layer reduced pellets, prevents the DRI is oxidized by CO2.

(2) The gas combustion to CO2. Because DRI is protect by the rising CO. So the whole process, from the material layer (reduction chamber) rising CO can be completely burned in the oxidation chamber into CO2, achieving high-temperature operation, providing a lot of heat, carbon-containing pellets can be used for heating and reducing, or preheat the air. Therefore, achieve high material layer operation to improve fuel efficiency and reduce fuel consumption.

(3) The high material layers in operation can shorten the average reduction time of each layer, to improve production efficiency.

3.3 "high temperature" and "high material layer" must be adopted at the same time

In the process, the high-temperature operation and high material layer operation must implement, both are indispensable.

If the material layer is not having the high temperature, the heat transfer is slow and difficult to shrink the upper DRI, making it harder pellets received lower radiation heat transfer.

If high temperature without high material layer, the single pellet reduction lack of bottom-up reducing protective atmosphere in the process of making DRI oxidants and melt under the condition of high temperature. So at the same time "high temperature" and "high material layer" must be implemented, both are indispensable. In a combination it makes this process has the characteristics of four high: high production efficiency, high energy efficiency, high metallization rate, high strength and density of DRI.

4 Single material layer test results and analysis

To compare the difference between high material layer and single layer at carbon consumption, productivity and the metallization ratio and other indicators, we firstly do the direct reduction test for single material layer. Test raw materials shown in Table 1, Table 2, bentonite: / iron ore = 1.5 / 100. Test parameters for C / O = 0.9, reduction temperature is 1200 ℃, pellet size is 17 ~ 19mm, reducing time was 15min, 20min, 25min, 30min, 35min, 40min. The results shown in Figure 4, Figure 5.

Figure 4 shows, although the single material layer pellet reduction for a long time, the DRI can shrinking greatly, due to the reduction of the pellet surface does not have enough protective atmosphere, make direct reduced iron re-oxidized to FeO, with SiO2 phase formation of low melting point slag, which leads to the pellet surface melting, influence heat transfer inside the pellet, metallization rate is lower.

Figure 5 shows that the metallization rate of single material layer pellets first increased and then decreased with time, the maximum rate of metallization is 51%:

(1)In the initial stage of the reaction, the reaction speed is fast for the pellets, the CO is enough to protect the reduced pellets against from re-oxidation, and therefore the metallization rate increased with the time (Figure 6a);

(2) In the latter stage of the reaction, the unreacted pellets gradually decreased, the reaction speed become slow, as well as the CO becomes no enough to protect the pellets against from re-oxidation. (Figure 6b).

Therefore, single layer pellet direct reduction results as follows:

(1) if the interior of the pellets is not fully reduction, the pellet metallization rate is low;

(2) if the pellets inside fully reduction, the surface DRI is re-oxidized easily, resulting in low metallization.

We can see that single pellet direct reduction is not only the low production efficiency, and can't change the disadvantage of the low DRI metallization rate.

5 High material layer test results and analysis

5.1 The pellets shrink in reduction process

Test material is the same to the material in single material layer. Because the reduced DRI shrinkage is essential for heat transfer and lower pellets reduction, we examined C/O=0.9, furnace reduction time for 50min, the DRI shrinkage after reduction. Pellet size is 17~19mm, pellets are five layers. The figure shows, the upper three-layer pellet diameter shrinkage to 70 to 74 percent of the original diameter, and for the fourth and fifth layer pellets were 80% and 88%.

We can see that heat transfer is the restricted step of the whole process, DRI contraction is critical to heat transfer of the material. At the beginning of reduction, the mode of heat transfer is radiation, after reduction the first layer of pellets volume shrinkage gap increases, it is beneficial for radiation heat transfer to the second layer of the pellets, and so on.......

5.2The effect of C/O on metallization

Test parameters: pellet size is 17 ~ 19mm, pellet layers is five layers, the material layer total height 80mm, furnace reduction time is 50min, C/O were 0.7, 0.8, 0.9, the crucible is removed from the furnace without removal re-factories. Figure 9 shows the effect of C/O on DRI metallization. The figure shows, (1) when the C/O is 0.7, because lack of reducer, which lead the low DRI metallization; (2) when the C/O is 0.8 and 0.9, the result is similar, 1~4-layer pellet metallization rate over 90%, the fifth layer pellets metallization rate was about 77%. Consideration for reducing carbon consumption, the test show that the choice C/O = 0.8 is the optimal value.

5.3 The influence of reduction time for DRI metallization

Test parameters: pellet size is 17 ~ 19mm, pellet layers is five layers, the material layer total height 80mm, C/O is 0.8, furnace reduction time was 45, 50min , crucible removed from the furnace without removal refractoriness. Figure 10 shows the reduction time effect on DRI metallization. The figure shows, (1) for 45min and 50min, the rate of the first four layers of metal are both high, about 90%; (2) when the reduction time is 45min, the fifth layer pellets metallization rate is low; when the time is 50min, the fifth layer pellets metallization rate is relatively high.

We use micrograph see the pellets after reduction in figure 11.By the figure we can be see that the first 3 layers of pellets reduction iron grain growth more completely, the iron grain is bigger, forming dense metal iron ball. Although 4 and 5 layer pellet metallization rate is higher, but the particles are easy to fall because of the slow heating, low temperature, loose structure, the iron particles is small.

Summary indexes of the high material layer and single layers in direct reduction test in table 3. The table shows, the metallization rate at high temperature and high material layers in direct reduction process is (87.6%); Productivity is high (55.47 kg/h.m2), which were significantly higher than the single layers in operation. Moreover, iron carbon consumption is low, about 372.08 kg/tHM; it is good for energy conservation and emissions reduction. With the increasing environmental pressure, to improve fuel is necessary for iron and steel industry, one of the advantages in direct reduction is reduce the fuel consumption and CO2 emissions are high temperature high material layer.

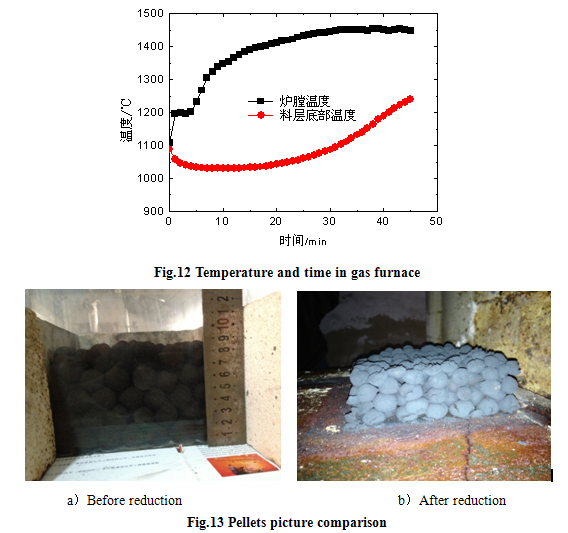

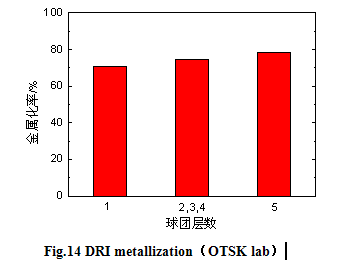

6 high material layer expanding test

On the basis of laboratory tests, we take the gas type furnace expansion test. Test raw material is the same with the laboratory research, as shown in table 1 and table 2.Test site is Tangshan outstanding science and technology co., LTD laboratory, test equipment is special gas reduction furnace, Northeastern university and Tangshan outstanding science and technology co., LTD research personnel to participate in the test. Parameters as shown in table 4, the temperature control curve as shown in figure 12, the DRI photo about carbon-containing pellets before reduction test and after reduction as shown in figure 13, DRI metallization rate as shown in figure 14.

As shown in figure 12 temperature–time control curve in gas furnace. the material charging temperature is 1200℃, after the charging material control furnace temperature not exceed 1200℃ within 5 min. After 5 min, rise the temperature to 1500℃ with rapid speed, the heating time is about 25 min. Then reduce to the temperature to1450 ℃. The total reduction time of Pellets is 45 min.

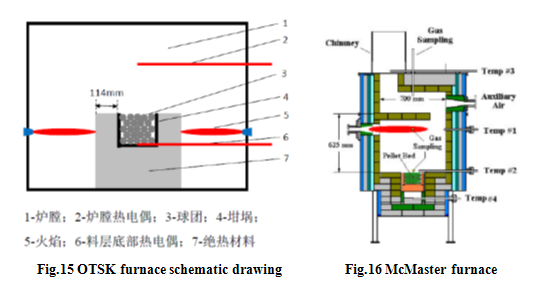

As shown in figure 14 for the metallization rate of the top-layer pellets (layer 1), middle pellets (2st, 3rd, 4th layers), the underlying pellets (5th) layer. Although the metallization the whole layers is lower than small electric furnace in the laboratory test, but the metallization rate is still higher than single coal layer pellet. Figure 14 shows, the underlying pellets metallization rate is the highest, about 80%. The material layers heat transfer from top to bottom, the top pellets to restore, after the lower reduction pellets. During the test, the upper pellet metallization rate is no higher than lower pellet. We can believe that the main reason based test equipment - the impact of the construction cause a gas furnace (Figure 15). The purpose of the furnace at the beginning of its design is heated reaction tank simulation reduction test, burner and exhaust port lower position shown in Figure 15 (a rear exhaust port in the furnace, not shown in figure. 15, the height is similar to flame height),

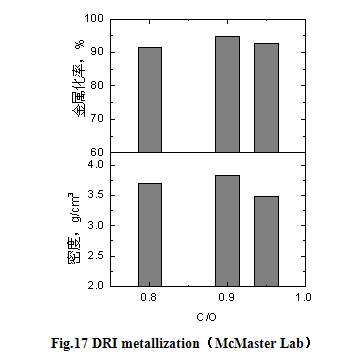

On previous test, we use a gas furnace making high material layer test at McMaster University in Canada, the furnace flame position is relatively high, while using the exhaust (Fig. 16), C/O is 0.8 to 0.95 range, balls DRI metallization rate reached more than 90% after the group's overall reduction, and have higher density, easy for long-distance transport (Fig. 17) [5]. Therefore, our group proposed location burner and flue gas outlet; pellet metallization rate will be further improved at further high temperature and high material layer test.

7 The core equipment of high temperature and high material layer technology - Development and application of the reciprocating car bottom furnace

7.1 The features of reciprocating car bottom furnace

Reciprocating car bottom furnace features is similar to the rotary hearth furnace, but the rotary hearth furnace is annular, which is rotated by an annular disk at bottom. The car bottom furnace is rectangular; the monomer composition trolley car columns form the bottom. Trolley car in a closed rectangular channel forward in turn, parallel and adjacent to the furnace and double furnace, the process through feeding, preheating, high temperature reduction, discharging and feeding, preheating, high temperature reduction, the car bottom furnace is a new type of reductive thermal equipment.

7.2The basic principles and industrial applications of reciprocating car bottom furnace

(1)The basic functions and principles of reciprocating car bottom furnace

There two car bottom furnace integrate by head-tail into a group. For the going furnace entrance, the trolley car after charged be pushed into the furnace. Go through preheating, high temperature reduction, cooling and then go out of the going furnace for discharging the DRI, after discharging, the trolley car be charged again and be pushed into the coming furnace, go through preheating, high temperature reduction, cooling and then go out of the furnace for discharging the DRI. This is a working cycle for one trolley car.

(2)The car bottom furnace reduction process characteristics

According to the requirements of high temperature and high material layer process, when the carbon contained pellets go into the middle parts of going furnace will generate a lot of reduced gas, the gas can be used in the coming furnace to protect the DRI against from re-oxidation.

(3) The industrial application of the reciprocating car bottom furnace

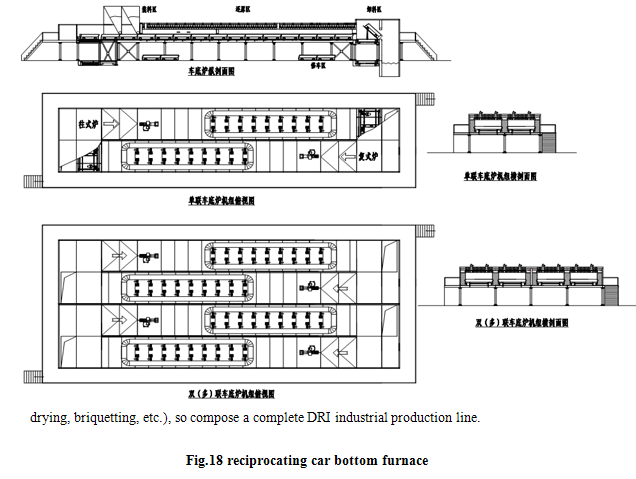

Reciprocating car bottom furnace can be designed as a single joint units (composed from two car bottom furnace), duplex (that is, composed from two single-bottom furnace unit), multi-joint (composed from two or more single-joint car bottom furnace), in certain furnace width, the unit length determines the scale of the production. The trolley round trip time constrain unit length, after the use of three-dimensional discharge technology, when the amount of production scale at 500,000 tons / year or less, we can choose a single joint reciprocating car bottom furnace unit, when the process is greater than the scale of the production of 500,000 tons / year, we can choose double (or United) reciprocating car bottom furnace unit as a production unit [6].

(4) The production line design car bottom furnace high temperature and high material layer process

According to the kind of material process requirements, when we use the high-grade ore as the raw material for metal pellets, the reciprocating car bottom furnace unit should equipped with some equipment such as raw material crushing, pelletizing, etc., behind the reciprocating car bottom furnace equipped with appropriate steps, such as a) hot charging melting furnace product high quality iron, or b) the cold metal pellets for steelmaking equipment transport, so compose a complete DRI industrial production line.

When can made cold-reduced iron briquettes (CBI) using low-grade refractory ore as raw material (including metallurgical slag), in front of the reciprocating car bottom furnace equipment with process device (such as raw material crushing, pressure the ball, etc.), at the behind of reciprocating car bottom furnace with process device (such as ball milling, magnetic separation, drying, briquetting, etc.), so compose a complete DRI industrial production line.

7.3 The technology advantage of car bottom furnace high temperature and high material layer process

Compared with other coal-based reduction process, car bottom furnace high temperature and high material layer process has the following advantages:

(1) high production efficiency, high energy efficiency, high metallization ratio, high DRI strength and density, which is the core advantage of high temperature and high material layer process, and it is the vehicle to adapt to the core of the furnace temperature and high technological requirements of the material layer;

(2)Save the land: In the case of the same size, car bottom furnace area of the rotary hearth furnace 45 to 55 percent;

(3) High work rate by year: Due to the small amount of vehicle maintenance, only the production car included in maintenance program, and the trolley can repair activities outside of the furnace, it can be kept realization furnace status line maintenance, the equipment operation rate is greater than 92%;

(4) Investment saves money, quick achievements

(5) The production line can be automated;

(6) Process a wide range: we can take both high-grade ore and multi-metal associated minerals as a raw material.

8 Conclusion and prospect

Sum up the main content above car bottom furnace high temperature and high material layer process

(1) operating characteristics: high temperature, high material layer,

(2) The production features" Four high": high efficiency, high energy efficiency, high metallization rate, high DRI strength and density.

(3) The development prospects: the DRI production, or special ore and iron scrap processing.

Since the development of high temperature and high material layer carbon-containing pellets direct reduction process of McMaster university in Canada, the European and American countries attach great importance ,and invested a lot of money for research [7].However, in China's the process does not develop. Through Tangshan outstanding science and technology co., LTD cooperating with northeastern university, we believe that car bottom furnace high temperature and high material layer process will have good application prospects.

(This article was published in “2014 annual meeting of non-blast furnace iron making collected works”)